Advancements in excavation equipment are transforming the construction industry, making processes more efficient, safer, and environmentally friendly. Modern technologies such as autonomous machinery, electric excavators, and 3D printing are at the forefront of this revolution. Autonomous machinery, equipped with sophisticated sensors and GPS, can perform tasks with unparalleled precision and minimal human intervention, enhancing safety by reducing the risk of human error. Electric excavators offer a cleaner alternative to diesel-powered machines, significantly cutting emissions and operating quietly, which is crucial for urban projects. Additionally, 3D printing allows for the creation of custom, durable parts on-site, reducing downtime and improving the overall efficiency of excavation operations. These technological advancements not only boost productivity but also contribute to more sustainable and cost-effective construction practices.

The Role of Autonomous Machinery in Modern Excavation

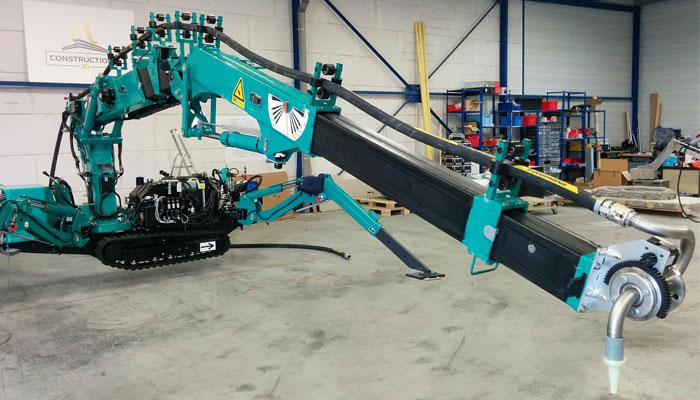

Autonomous machinery is revolutionizing the excavation industry by increasing efficiency and safety. These machines, equipped with advanced sensors and GPS technology, can perform tasks with high precision and minimal human intervention. They reduce the risk of accidents by eliminating human error and can operate continuously without fatigue, significantly speeding up project timelines. Autonomous equipment also allows for real-time data collection and analysis, improving decision-making and project management.

Photo source | credit: https://www.pexels.com/search/excavation%20equipement/

Electric Excavators: Benefits and Challenges

Electric excavators are gaining traction as an eco-friendly alternative to traditional diesel-powered machines. They produce zero emissions, making them ideal for projects in urban areas with strict environmental regulations. Additionally, they operate more quietly, reducing noise pollution and improving conditions for workers and nearby residents. However, the challenges include limited battery life and higher initial costs, though advancements in battery technology and economies of scale are expected to mitigate these issues over time.

Photo source | credit: https://www.pexels.com/photo/excavator-machine-truck-close-up-photo-11218749/

The Impact of 3D Printing on Excavation Tools

3D printing is making significant inroads in the production of excavation tools and components. This technology allows for the creation of custom parts that are lighter, stronger, and more durable than traditionally manufactured ones. 3D printing can produce complex geometries that enhance the performance and efficiency of excavation equipment. Furthermore, it enables rapid prototyping and on-site manufacturing, reducing downtime and the need for large inventories of spare parts.

Photo source | credit: https://www.3dnatives.com/en/wp-content/uploads/sites/2/FS_construction3D.jpg